how to prep a car for paint after soda blasting

As long as you properly prep the vehicle before painting paint adhesion is not an issue. Prevention is always better than a cure and once we remove the rust we always.

Soda Blasting To Clean Engines

Protect metals after abrasive blasting with powder coating or ceramic coating.

. Paint shops in my area suggested leaving it alone after soda blasting. Use Air to blow out any latent soda. If it cannot be perfect let them blast it.

Sandblasting uses sand particles alone to scrape the surface of a vehicle with small particles propelled at a high pressure. This prevents re-rusting which will occur rapidly if any moisture is present. When it comes to stripping paint rust oil and grease from the steel body of a vintage car a variety of methods can be used but some of the most common are sandblasting soda blasting and dustless sandblasting.

Use After Blast after. Allow our team to assist you with choosing the proper equipment to give you the desired surface prep finish. Use After Blast after blasting or sanding metal then paint prime or powder-coat.

Coating failures after soda blasting can usually be traced back to no pre-paint preparation or poor preparation or incorrect preparation. Prep 2 metal panels with w g remover prep with 80 grit on a da clean againprime 1 panel with epoxy prime the other with etchprior to the severe safety and health restrictions put on silica sand the term sand blasting was commonly used. How To Prep A Car For Paint After Soda Blasting I would use a compressor and blow out any blasting residue and then seal it.

May 11 2020. Use after abrasive soda blasting or sandinggrinding operations to assure of a clean paint. I had the same experience JohnC when I looked into this for my car.

In areas where tarping is not practical start with a pre-soaking of the plantings and ground the day before with tap water. Sand the car to rough the surface 5. Doesnt recomend it.

Surface Cleaning After Blasting. You will be suprised how much gets trapped in small areas. It is very difficult to see the oxidation but it has started.

They were equally empathic that soda needs to be fully neutralized before paint. Proper Surface preparation will properly prepare your substrate for a subsequent finish and leave it in a raw state. Use a phosphate product Like POR-15 METAL READY over the body to coat the metal and protect from rusting.

For classic cars and restorations though a soda blast is. Second issue is water accelerates oxidation or rust. Soda is caustic and is easily activated with moisture.

Use After Blast after blasting or sanding metal then paint prime or powder-coat. In a Perfect world. Baking soda is a wonderful media that allows you to do things that no other media will accomplish but you need to educate yourself about the media and follow a few simple steps after blasting.

Repeat until clean and no traces of Soda. Cal Blast uses a sodium carbonate material which is worlds softer than sand mediaa substance common in industrial applications. Coating failures after soda blasting can usually be traced back to no pre-paint preparation or poor preparation or incorrect preparation.

A local guy swears by it and trys to sell it to everyone because he can leave a bare sodablasted panel outside for a couple weeks with no rust formation. Your media blaster removes the paint and filler from the body spends days cleaning up the media mess and then takes more time in a clean environment like a real paint booth to apply quality epoxy primer. BarryK of Southern Polyurethanes said the same thing when I asked him about how to prep.

Wash the car down with a vinegarwater solution to remove any of the soda residue. Anything else is less than perfect. Follow removal of the tarps with a copious tap water wash down of the plantings.

A low Ph acidic and a high Ph basic with both eat metal and oxidize. For more info and to purchase. I have read and heard a lot of problems with primer adhesion.

The clean rust-free metal that remains needs to be treated as soon as possible after abrasive blasting. After washing use a new cloth and fresh clean. No matter how fast you get the metal dry oxidation has started.

I would use a compressor and blow out any blasting residue and then seal it. Scrub with a red scotch brite and keep the metal wet as you are scrubbingdo. Be sure you are ready to apply that finish so rust will not occur.

Allow our team to assist you with choosing the proper equipment to give you the desired surface prep finish. Warm or hot soapy water with a sotch brite and preferably using a pressure washer to rince is the best way I have found to remove the soda. Flood all plantings with tap water immediately after blasting.

After sandblasting I wipe the entire frame down with a final prep cleanerto remove the excess residue. Spray wipe and repeat until clean Aqueous cleaners and phosphoric acid clean and etch the metal Also protects against flash corrosion After Blast cleans degreases.

Soda Blasting Equipment Soda Blaster Case Study For Muscle Car Restoration

Midlife Classics Preparing Your Vehicle For Sodablasting

Dustless Blasting Strips A 63 Impala In Under 1 Hour Youtube

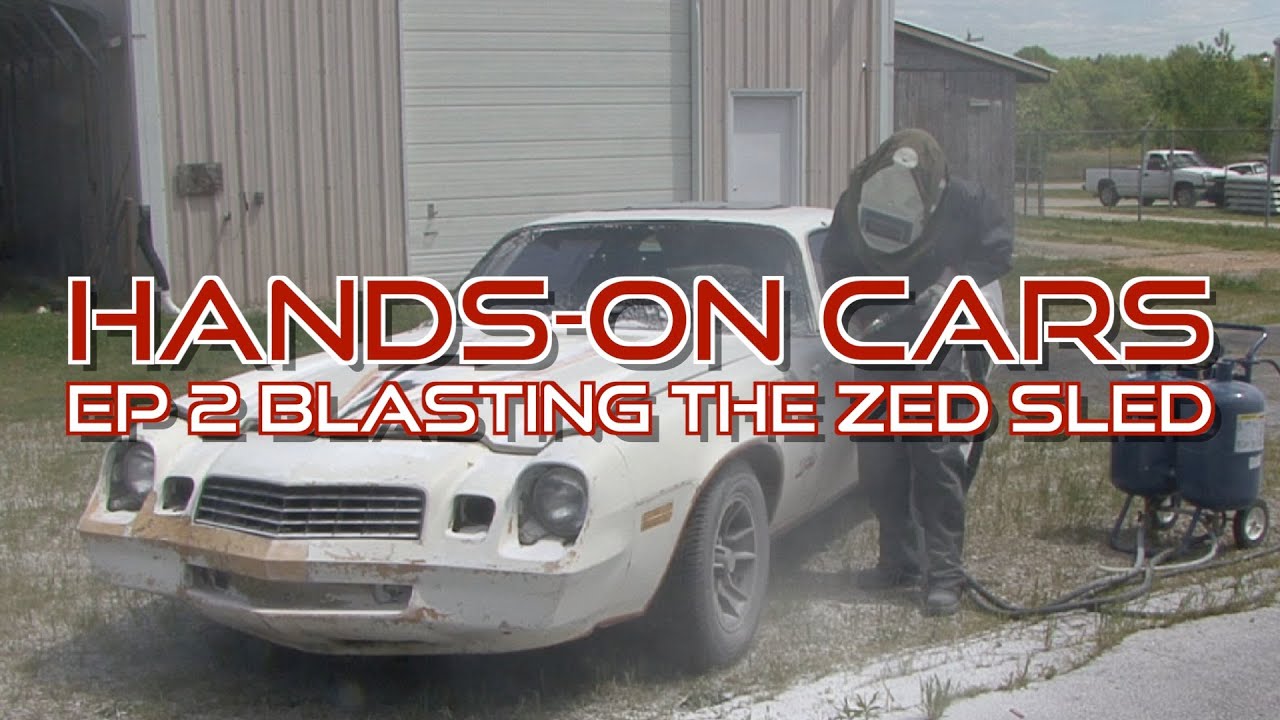

How To Soda Media Blast A Car Hands On Cars 2 From Eastwood Youtube

What Is Soda Blasting American Dry Stripping

Specialty Projects Crystal Soda Blast

Soda Blasting Equipment Soda Blaster Case Study For Muscle Car Restoration

Thesamba Com Body Paint View Topic Soda Blasting What Do You Do After It Is Done

Soda Blasting Equipment Soda Blaster Case Study For Muscle Car Restoration

Automotive Machine Shop And Speed Shop Dlk Auto Parts Dlk Performance Soda Blasting

Know The Pros Cons Of Soda Blasting And Sand Blasting By Henry Russel Medium

Soda Blasting Vs Sand Blasting Abitl Finishing Inc

Soda Abrasive Blasting Mustang Wheels With Small Job Blasting System From Eastwood Youtube

The Advantages Disadvantages Of Soda Blasting

Soda Blasting Equipment Soda Blaster Case Study For Muscle Car Restoration